Key Differences Between Tandem and Cluster Steel Rolling Mills

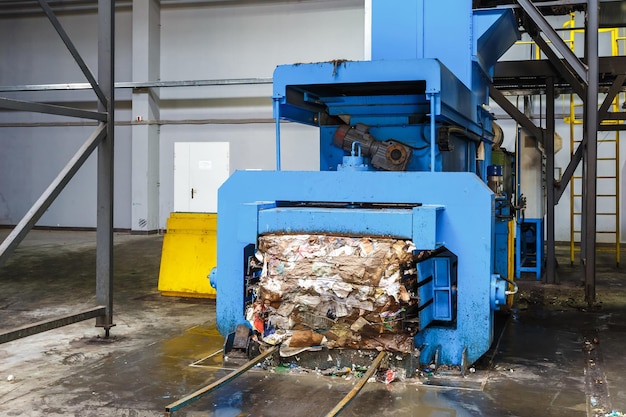

A vast amount of machinery is used in the steel industry to create high-precision finished products. Quite a few of these are essential in the manufacturing process. These machines are crucial in forming steel into sheets, strips, bars, and various other shapes. The two most widely utilized varieties are tandem rolling mills and cluster rolling mills. Although both steel rolling mills are used to process steel efficiently, they differ significantly in their working mechanisms, applications, and advantages. Tandem vs. Cluster: A Structural and Functional Comparison Steel rolling mills are critical pieces of metalworking equipment widely used in industries that rely on steel. Although tandem and cluster scenarios solve similar things, they work and produce results quite differently. Design and Configuration In a tandem rolling mill, multiple rolling stands are arranged in a series. Each stand reduces the thickness of the material, and the material is continuously passed through the entire line. This configuration is perfect for high-speed production and consistent results. Often used in sheet or strip metal processing, these mills provide high volume with minimal handling. Cluster rolling mills are more compact, as they have several backup rolls that support the smaller working rolls. The arrangement also controls roll deflection, resulting in